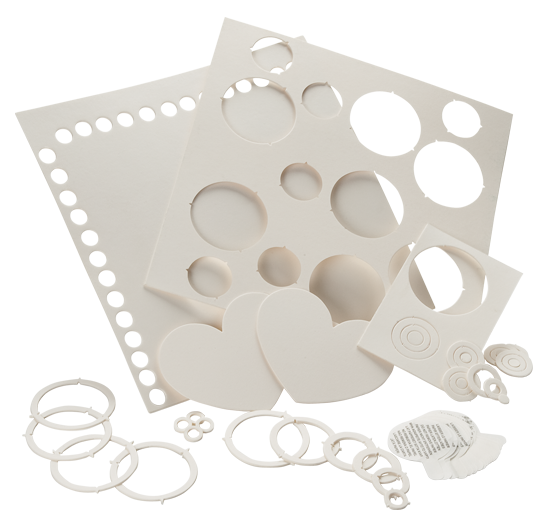

Gaskets/Boards/Spacers

Applications:

Gaskets*

Gaskets fill the space between two adjoining surfaces while under compression. Most adjoining surfaces are irregular. Gaskets allow the two irregular surfaces to meet. Gaskets are commonly made from metal, rubber, silicone, cork, and other natural and synthetic materials. The material choice is complex and dependent upon the application. Most times metal gaskets must be compatible with other metals being used and have risks such as corrosion and oxidation. A new material which is compatible with any metal, uniform in size and thickness and highly durable is Aquasol® Water Soluble Board or Aquasol Heat Resistant Board.

*U.S. & Foreign Patents Pending.

Aquasol Water Soluble Board* and Aquasol Heat Resistant Board

Aquasol®Water Soluble Board has the same unique features as water soluble paper, with the exception of density and dissolve time. Aquasol®Heat Resistant Board can withstand extremely high temperatures. Sturdy yet lightweight, these boards can be die cut into any shape (elliptical, round or O-ring) and in a variety of thicknesses and densities. The denser the water soluble board, the lengthier the time to dissolve. Your custom designed profile will allow for very high compression and an extremely tight seal along the ridges of the gasket.

*U.S. & Foreign Patents Pending.

Spacers*

*U.S. & Foreign Patents Pending.

Benefits of Gasket/Board/Spacers

Environmental-Friendly

Aquasol’s Water Soluble Paper is 100% eco-friendly because it dissolves naturally with the introduction of water.

Size and Shape

Aquasol Spacers can be made in many sizes, shapes, and densities depending on your needs. Inquire today with your specifications.

F.A.Q.

How do the Spacers dissolve?

With the introduction of water, the Spacers will dissolve in approximately 2 minutes, but could be more, depending on the density.

CONTACT INFO

716.546.8888

80 Thompson Street

North Tonawanda, NY 14120 USA